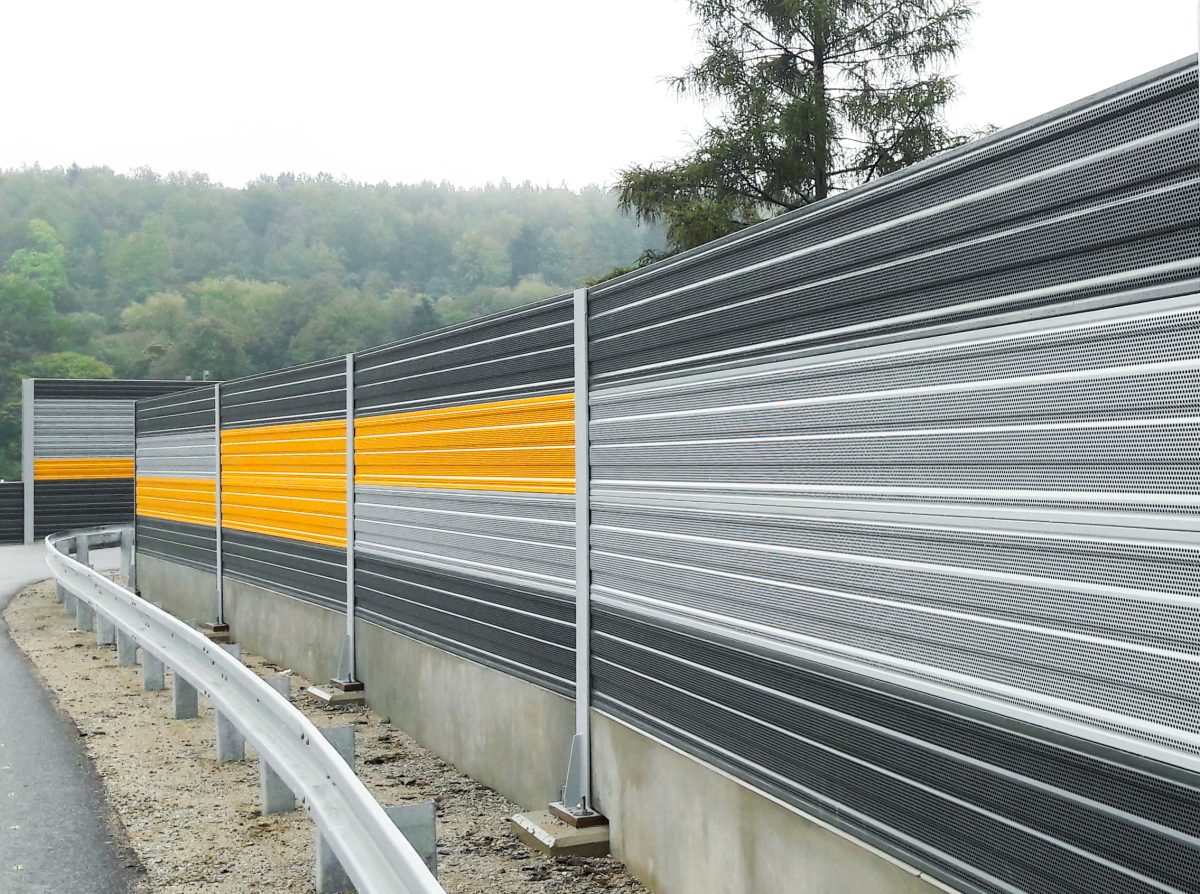

The best combination of acoustic performance, durability, price and maintenance costs.

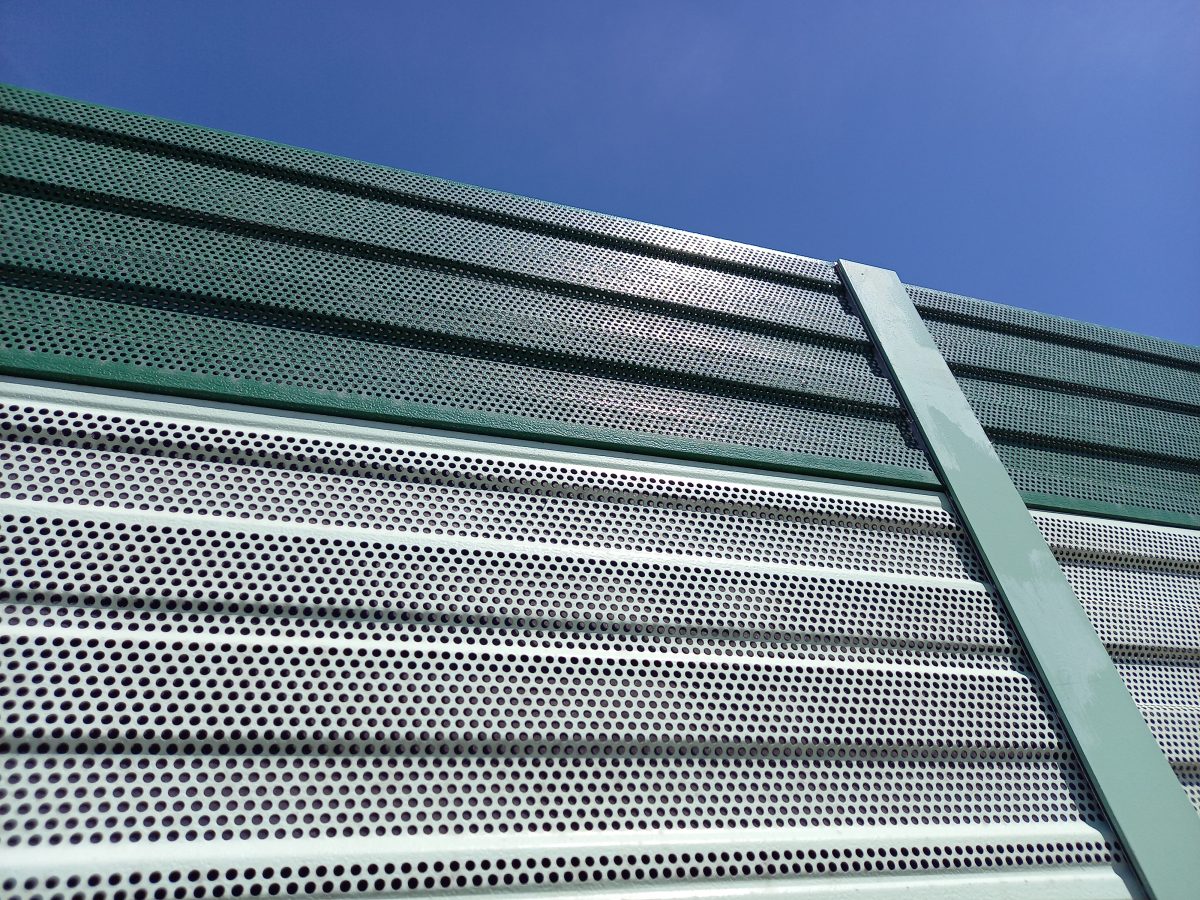

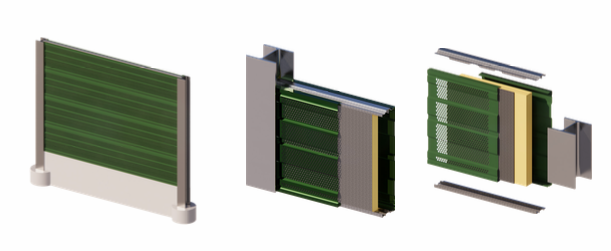

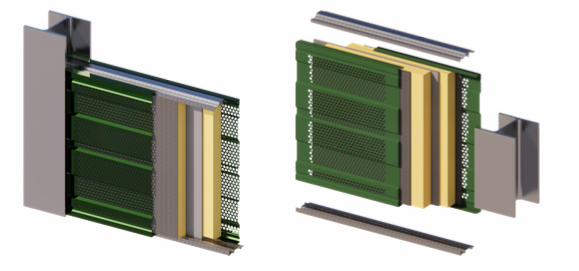

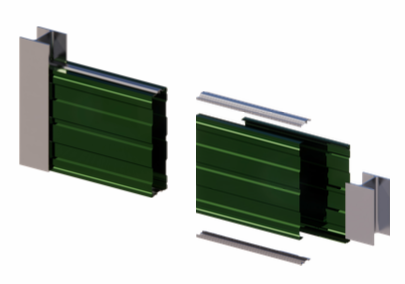

CALVERO acoustic aluminum panels are used for the construction of acoustic screens to protect against noise. We produce panels that are absorptive on one side, absorptive on both sides and reflective. Our aluminum panels are among the most effective

solutions for combating noise. Our products are characterized by high durability (estimated lifespan – a minimum of 30 years), and do not require special maintenance after installation. A wide range of colors allows the construction of aesthetically pleasing screens

acoustic.